|

|

| |

|

| |

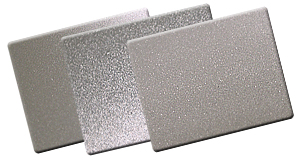

| * Beads Blasted Finish |

¡@¡@Stainless steel, to spherical silica spherical sand, and impose appropriate force impact to generate as bright pearl on the surface, known pearl stainless steel plate. Because of silica inert material, stainless steel and impact, will not undergo chemical changes do not change the stainless steel. Spherical surface of the collision because it is very smooth, not James dirt and hand marks.

¡@¡@This stainless steel rust-proof and follow-up maintenance, far better than in the general sandblasting used by the alumina, silicon carbide or the Gang Sha materials such as sand. Processing can cope with Screen Printing photographic camera or card Code of the Federal Republic of Germany, including through the formation of the special artistic effects. Due to sand wood can be fully recovered and not pollute the environment, and general non-chemical etching can do.

¡@¡@The greatest work of size: 4 feet ¡Ñ 4M. |

|

Beads Blasted Finish

Patent of invention 134090th (20 year time) self-restraint |

| Material |

Stainless steel(SUS - 304¡B316) |

| Thickness |

0.1 m/m ~ 3.0 m/m |

| Greatest size |

1219 m/m * 4000 m/m |

|

| The pearl surface also recently received the superficial refining methods which welcome, mainly sand-blasts method, even, high speed hit in steel plate surface, forms the beautiful surface. |

|

| |

|

|

|

|

|

| |

|

|

|

Factory 1¡JNo.11, Ln. 36, Sec. 3, Fudan Rd., Pingzhen Dist., Taoyuan City 324, Taiwan (R.O.C.)

Factory 2¡JNo.6, Ln. 97, Sec. 3, Fudan Rd., Pingzhen Dist., Taoyuan City 324, Taiwan (R.O.C.)

Tel¡J(03)4915966¡E(03)4939763¡@Fax¡J(03)4910598

EMAIL¡Gtaoshuo@ms17.hinet.net |

|

|

| |

|

|